Table of Contents

Did you know that a pinhole leak in your hydraulic hose can release hydraulic fluid with enough pressure to penetrate both clothing and skin?

Did you know that a pinhole leak in your hydraulic hose can release hydraulic fluid with enough pressure to penetrate both clothing and skin?

Employees can become complacent around hydraulic systems and that is when mistakes are made, maintenance is neglected and injuries occur. While most common injuries may be just a result of slip and fall, three more serious dangers exist: burns from hot hydraulic fluid spray, injuries sustained from falling or whipping hydraulic lines and injection of hydraulic fluid into the skin.

A hydraulic fluid injection is perhaps the most dangerous because it appears benign at the beginning so the urgently needed medical care is often postponed. The result is likely to be painful, gruesome and life changing. Learn more about oil injection injuries and how to respond if they happen at your work. Warning - pictures are graphic.

To remain safe, hydraulic systems need to be properly maintained. All hydraulic hose assemblies need to be periodically replaced. Be proactive. Learn how to determine when to replace hose assemblies, establish a maintenance schedule and follow it consistently.

Your schedule should include checking all hoses for cuts, abrasions, cracks, and other signs of damage. Never touch a pressurized hydraulic hose assembly with any part of your body. If you suspect a leak, use a piece of cardboard, wood or sheet metal to locate it. Also check fittings; if they're damaged, they can also result in a failure and injury.

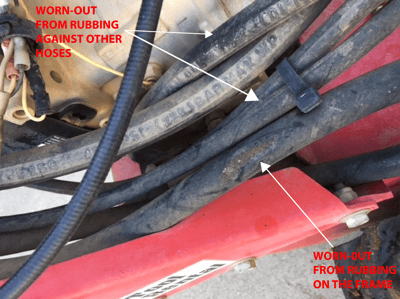

Here are some conditions to watch out for - and to avoid if you are installing replacement hose assemblies:

- Hoses rubbing against each other or against other parts - causes abrasion, leading to hose failure.

- Hose maximum working pressure rating above the system maximum pressure rating - including pressure spikes.

- Correctly fabricated hose assemblies - hoses must be compatible with hose ends used and hoses must be inserted all the way into the fittings prior to crimping. Only well trained personnel or reputable supplier should be trusted with hose assembly fabrication.

- Hose bend radius too tight - refer to manufacturer's specifications

- Hose bend beginning at the fitting

- Twisted hoses

When specifying hoses in your design or replacing hose assemblies, use S.T.A.M.P. rules for hose selection to make sure you obtain the right hose for your application. Only use fittings designed for use with the hose you select.

Posted by Joni Scott

![Parker P1D Cylinders Improve Pneumatic System Safety [During Power Outage]](http://www.mfcp.com/hs-fs/hubfs/images/product/Pneumatic-Actuator-Products/Tie-Rod-Pneumatic-Cylinders/parker-P1D-series-rod-lock.png?width=400&name=parker-P1D-series-rod-lock.png)