Table of Contents

Everybody does it, but you may want to reconsider...

|

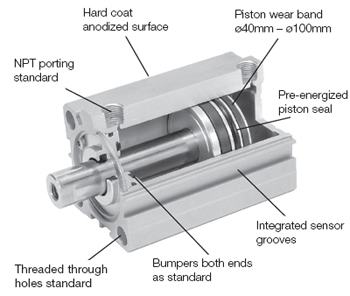

Unlike hydraulic hose and fittings, industrial hose and couplings are usually made by different manufacturers. While many industrial hose manufacturers suggest couplings to use with their hose for a given application, they cannot guarantee the assembly will perform to the rated burst pressure of the hose. Industrial hoses are used to convey acids, chemicals, gasoline, abrasive materials, LP gas, solvents, welding gases and slurries. Many of the materials conveyed through industrial hoses can cause serious harm to workers and the environment. However, the hose assemblies that are used to transport these hazardous materials have no established safety standards! |

There have been rigid standards for hydraulic hose assemblies for over 50 years, but the same is not true for industrial hose assemblies.

That is why when mixing industrial hoses, couplings, and clamps made by different OEMs, people are taking a gamble on the integrity and safety of the industrial hose assemblies they build.

If you use parts made by two or three manufacturers to build your industrial hose assemblies, you are not alone. The Majority of mechanics and maintenance managers do just that – but what are the odds?

- There are more than 200 industrial hose manufacturers worldwide that do not manufacture any couplings.

- There are dozens of end-connection (fitting) manufacturers that have little or no knowledge of the compressibility, elasticity, or flow of rubber compounds that have wire or fabric reinforcement.

- There are dozens of clamp (attachment) manufacturers who have little knowledge of how much compression is needed to enable the rubber and reinforcement to hold the fitting under pressure.

Now consider the thousands of distributors/fabricators who make hose assemblies without any industry standards. Would you be surprised to learn that litigation for industrial hose is over 100 million dollars annually in the United States?

Luckily, there is a solution to the uncertainty resulting from the lack of industry standards: Circle of Safety Program

Circle of Safety Program

|

Parker’s Circle of Safety Program is a tool that allows Parker distributors to select Parker industrial hose and fitting/attachment combinations that work. The Circle of Safety also establishes Parker's Industrial Hose Division as a single accountable source with a specific performance guarantee. This guarantee protects distributors and end users from accidents, unplanned downtime and increased liability associated with failed industrial hose assemblies. In short, using the Circle of Safety is a safe bet. |

Posted by Marek Bobik