Table of Contents

Did you know that over 100 million gallons of hydraulic fluid are lost each year due to preventable leaks?

Hydraulic leaks cost many companies a lot of money in man-hours to find and fix the repairs, replacement hydraulic oil, and machine down-time. Hydraulic fluid leaks can also lead to possible EPA (Environmental Protection Agency) monetary fines or, worse yet, plant closures. Most hydraulic leaks occur at threaded connections. The following are causes of, and tips to prevent, leaks:The first step in preventing a hydraulic fluid leak is in design:

- Design a system with as few joint or thread connections as possible.

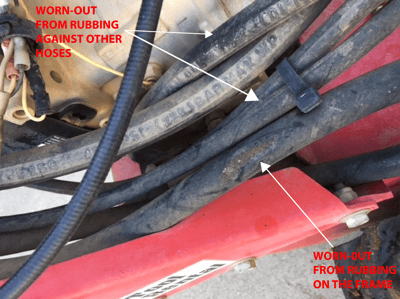

- Properly support the tubes, pipes and hoses conveying the hydraulic fluid. Vibration could result in joint or connection failure.

Poor repair and maintenance practices can also contribute to leaks in the system:

O-ring failure could be the cause of leakage.

- Make sure the O-ring material is compatible with the media being conveyed

- Make sure the O-ring material is rated for the expected temperature range

- Make sure the O-ring did not get pinched during installation

Improper connection assembly is another common source of hydraulic leaks:

- Over-tightening a JIC connection

- Using a 45° flare tube nut instead of a 37° flare in JIC tube end connections

- Missing sleeve on JIC or SAE flare tube connections

- Missing, or incorrectly applied, thread sealant on pipe threads

- Bite not preset correctly in a bite-type connection

Become an Expert on Port End Assembly

Knowing the proper assembly techniques for each thread type is essential to maintaining a leak-free hydraulic system. There are too many connection types to cover in one blog, so download The Port Assembly Guide and keep it handy in your tool box.

The Port Assembly Guide has detailed instructions on assembly, as well as troubleshooting guides for the following connections:

- Port End Assembly

- Parallel thread ports

- Adjustable port end assembly

- Non-adjustable port end assembly

- Tapered thread port assembly

- Flange port assembly

- Troubleshooting port end connections

- Tube end assembly

- Tube end preparation

- O-ring face seal assembly & troubleshooting (UPTC, ORFS, Parker Seal-Lok)

- JIC assembly & troubleshooting (37° flare, Parker triple-lok, Parker triple-lok 2)

- Bite-type assembly & troubleshooting (Parker ferulok, Parker intru-lok, Parker EO, Parker EO2)

- Bulkhead locknut assembly

- Pipe swivel assembly

Posted by Roger Winchell

Published Tue, Mar 26, 2013 @ 12:23 PM