Parker General Purpose Quick Couplings | Push to Connect

The Push-To-Connect design permits one handed connection when the coupler half is rigidly mounted.

To Connect and Disconnect Parker manual connect air couplings using both hands, use manual connect style couplings instead.

CAUTION: When disconnecting couplings under pressure, firmly hold both halves of the coupling. The residual pressure may result in hose whip, which can lead to injury and damage of property.

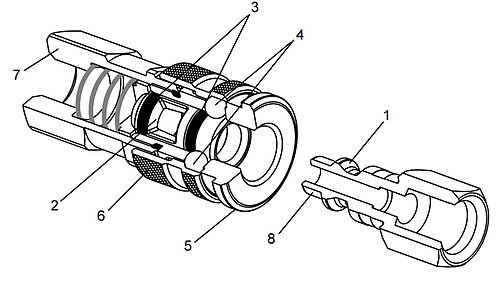

Component Part Features for Parker Pneumatic Push-To-Connect Couplers | Series RF, HF, HA & UC

(For 30 Series Component Part Features go to 30 series Component Part Features)

- Precision machining, hardened wear points* and solid barstock construction provide long life even in rugged applications.

- Tubular valve with large flow passages delivers high air flow with minimal pressure drop for efficient performance. The tubular design provides 360° support for both the valve seal and the mating nipple for long service life.

- Precision molded seals form a “bubble tight” seal for reliable operation within rated working pressures. Standard seal material is Nitrile. Ethylene Propylene, Fluorocarbon and Neoprene seals are available as options.

- Proven ball locking mechanism with large numbers of hardened steel or stainless steel locking balls evenly distribute the load to resist wear and provide positive connections. The ball locking mechanism also provides accurate alignment and allows a swiveling action to reduce hose torque.

- Integral sleeve guard protects the sleeve and resists accidental disconnects by allowing the coupling to ride over obstructions without the sleeve being retracted.

- Knurling and/or grooves on sleeve provide a gripping surface for ease of operation.

- Wide range of end configurations are available to meet specific needs. Parker push-to-connect type couplings are available with male pipe thread, female pipe thread, standard hose barb, and Push-Lok hose barb**.

- Parker 20, 30, HF, and E-z-mate Series couplings mate with industrial interchange design nipples.

- Push-to-connect design permits one-handed connection when the coupler half is rigidly mounted.

* Steel nipples only.

** Push-lok hose barbs are designed for use with Parker Push-lok hose and do not require clamps.

Parker Pneumatic QC Options

SLEEVE-LOK

All sizes of 10, 20, 30, 50, and 70 Series couplers can be furnished with Locking Sleeves.

Place suffix letters -“SL” (Sleeve-Lok) after regular catalog number. Example: B33-SL

OPTIONAL SEAL MATERIALS

Available for 30 Series Parker Pneumatic Couplings

Ethylene Propylene - temperature range from -65°F to +400°F (use part number suffix "W" to specify)

Fluorocarbon - tempreature range from -30°F to +400°F (Use part number suffix "Y" to specify)

Contact us with any questions regarding options not listed.