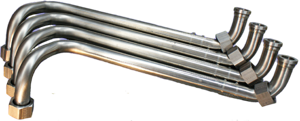

Custom Tube Assemblies

|

Motion & Flow Control Products, Inc. specializes in the production of high-quality hydraulic bent tubes and assemblies in steel, stainless steel, and copper. In addition to custom tube assemblies, we specialize in custom hose/tube combination assemblies. Take advantage of our quick response to your request for tubing quotations. We can produce a single one-of-a-kind tube assembly as well as large production runs. |

Why choose a custom tube assembly?

- Tube assemblies last longer than hose assemblies

- Tube assemblies are not affected by UV exposure like rubber lines

- Stainless steel tube assemblies resist internal and external corrosion

- Stainless steel tube assemblies are weather-resistant and do not require additional painting or rust inhibitor application

- Tube assemblies offer a smaller bend radius than rubber lines for precise positioning in tight spots

- Tube assemblies can offer a smaller diameter than hoses for your high-pressure application

- Tube assemblies are generally lighter in weight than hose assemblies

- Tube assemblies decrease flow turbulence, thus increasing machine performance

- A well-routed tube assembly makes tracing your lines easier so that you will be able to identify issues quickly

- If you are an OEM, your equipment will look neater (not like a nest of snakes), and this can contribute to your bottom line

- Tube assemblies are competitive with the cost of our hose assemblies

Precision tube bending capabilities

- 3/16" to 1 1/2" diameter tubing

- Brazed, flared, or flanged tube end treatments are available

- CNC tube benders

- Non-contact laser coordinate measuring machine (CMM) to ensure tube bending accuracy

- One-of-a-kind to large volume production runs

- We can create bent tube assemblies from:

- Hand-drawn sketches

- Engineering drawings

- XYZ coordinates

- Reverse engineering from samples

Our central production facility can handle large production runs, R & D support, and provides other engineering services.

Our ParkerStores have tube bending capabilities for small size walk-up orders at each of our locations.