Pressure ratings for metal tubing shown here are for dynamic systems. A vast majority of systems where our fittings are used fall in this category. However, there are applications, such as hydraulic jacks, where the system pressure is essentially static once it is pressurized. For this type of an application, Parker allows the fittings to be used at higher pressures.

A system in which the operating pressure fluctuates, in accordance with load, up to a maximum pressure limited by the relief valve. In addition, the system may also experience shocks, vibration and temperature excursions.

Example: A backhoe.

A system that, once pressurized, is essentially free of pressure fluctuations, shock, vibration and temperature excursions, with such pressurizations not exceeding 30,000 in the life of the system.

Example: A hydraulic jack.

The dynamic pressure ratings are based on a minimum design factor of 4. In other words, the fitting is capable of holding a pressure equal to 4 times the rated pressure before leakage or failure. For static applications, the design factor can lowered to 3, so the static pressure rating is 1/3 higher than the dynamic pressure rating.

STATIC PRESSURE RATING = DYNAMIC PRESSURE RATING X 1.33

Example: Static pressure for a fitting rated to 3,000 PSI is 4,000 PSI (3,000 x 1.33 = 4,000).

Some Parker fittings and adapters are capable of performing at a higher pressure than their published pressure ratings. For information about higher pressure ratings, contact Parker Hannifin Tube Fittings Division or Motion & Flow Control Products, Inc.

The dynamic pressure rating for tubing is calculated using LAME's Design Pressure Formula:

|

For thin wall tubing (D/T = 10 or more), use the following formula: P = 2ST/D |

|

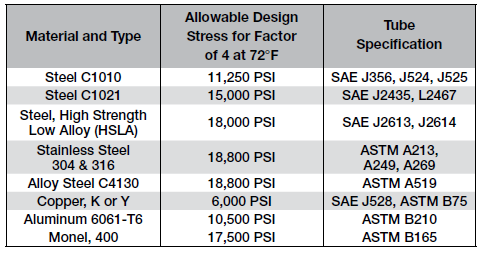

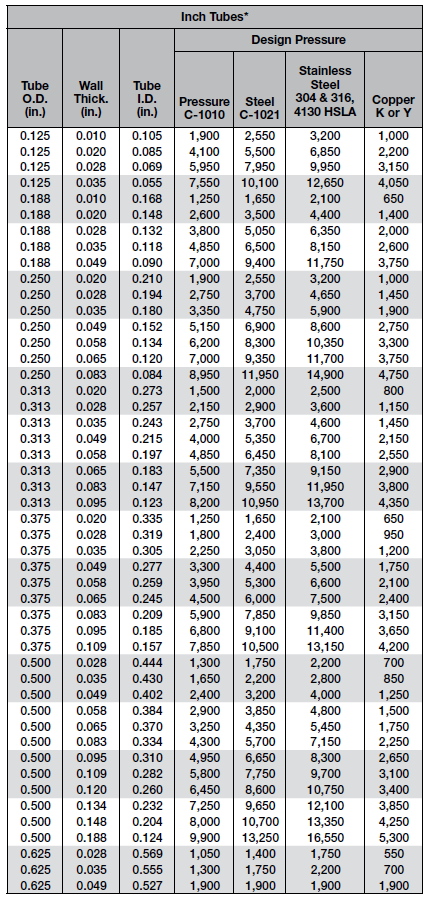

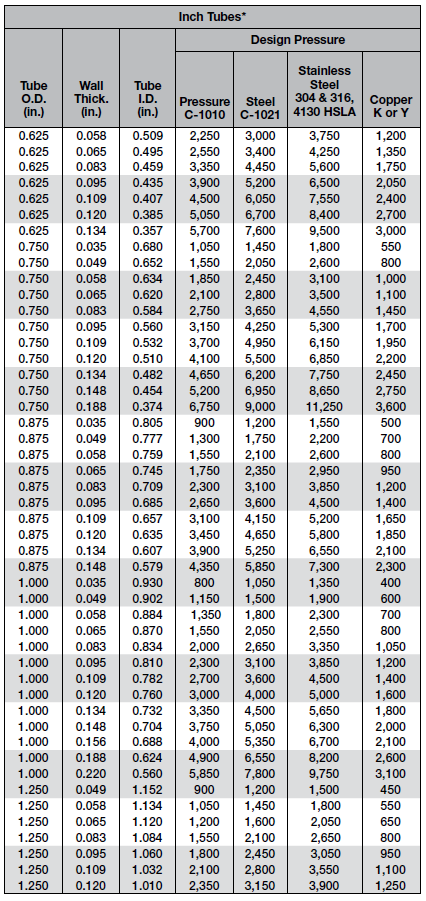

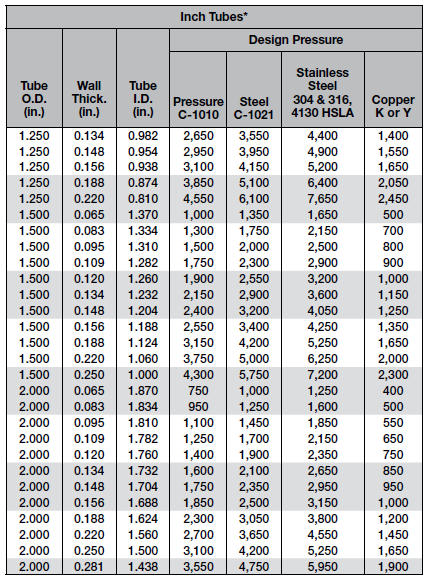

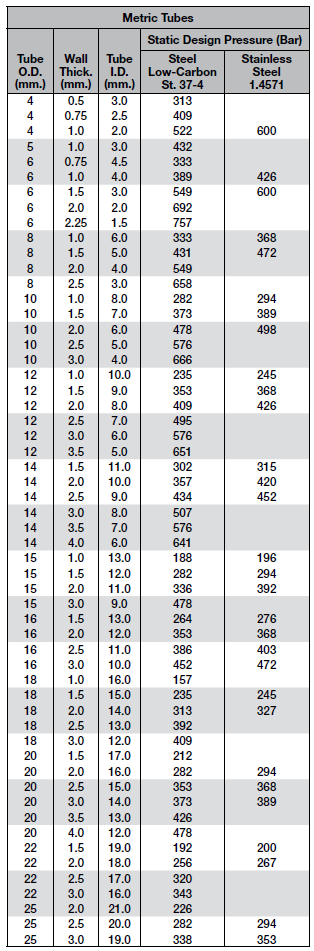

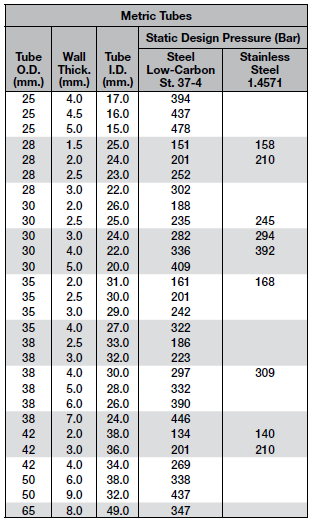

LAME's formula was used to calculate values in the pressure rating tables for inch and metric tubing provided below.

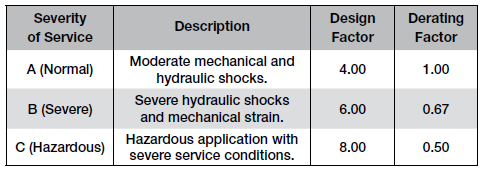

If any of the factors in the table below apply to your situation, multiply the maximum working pressure from the pressure rating tables above by the corresponding factor to arrive at the corrected maximum working pressure.

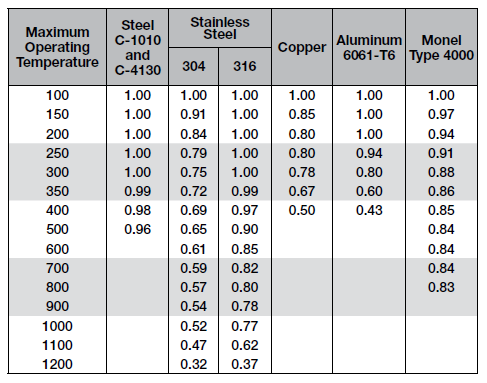

If the maximum working temperature of your system is above 100°F, use the table below to determine the derating factor.

|

|