Table of Contents

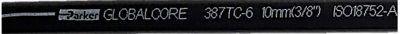

Have you noticed all the writing on your hoses that are manufactured by Parker Hannifin? To most people it looks like mumbo jumbo, to others it is an indispensable source of information about hose identification. The lay line runs the length of the hose with information to assist in the re-ordering of an existing hose.

Printed on the hose is the manufacturer, part number and the size (inside diameter), maximum working pressure, industry standards that the hose meets and the manufacturing date.

|

Manufacturer designation - in this case, Parker |

|

The part number is 451 TC; the hose size inside diameter dahs-size is -12 (= 3/4") |

|

Working pressure in Mega Pascals and pounds per square inch |

|

Industry standards the hose complies with (SAE 100R 17) |

|

The date code (2nd quarter of 2010) |

The date code is very important because it can be used to determine when hose replacement is needed. The Society of Automotive Engineers (SAE) specifications states that shelf life of bulk rubber hose is 10 years from the date of manufacture and is considered unlimited for thermoplastic hose, if stored in subdued light and controlled temperatures with no fittings attached.

Sometimes you may also see No-Skive printed on some of your hoses.  Skiving refers to removing (or shaving) part of the hose cover and/or inner tube prior to attaching hose ends. No-Skive means the hose and fittings are designed to work without this step. Parker offers more No-Skive hose than any other manufacturer.

Skiving refers to removing (or shaving) part of the hose cover and/or inner tube prior to attaching hose ends. No-Skive means the hose and fittings are designed to work without this step. Parker offers more No-Skive hose than any other manufacturer.

So what is the advantage to you? The hose core is not exposed to possible damage since the cover or inner tubes do not have to be removed to attach the crimped fittings. A No-Skive hose speeds up the time of a hose assembly and there is no additional equipment or clean up needed.

The lay line can also be used as a visual index when routing and tightening the assembly to ensure the hose is not twisted or kinked.

The information on your hose can also be used when re-ordering a hose and using the STAMP method. Knowing what you are looking for will save money and time spent on having a hose made.

Posted by Joni Scott