No order too large

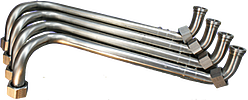

We can produce large production quantity runs of steel, stainless steel and copper tube assemblies and unitized hose/tube assemblies to match your application.

CNC tube benders assure the uniformity of the production run tube assemblies.

Production run tube assemblies are checked by CMM to ensure accuracy.

Meeting your specs

To ensure that all tube assemblies comply with our customers' specifications, our highly trained technicians utilize:

- CMM laser measuring equipment (Romer Stinger II inspection arm)

- CNC tube benders

- Special small manual tube benders

- Flaring, flanging and brazing tools – including use of Parker Parflange technology

- Other custom-engineered and custom-built specialty tube prep machines

Custom Tube Assembly Production Runs

Tube bending specialties:

|

We are experts in the following areas of tube bending:

|

State-of-the-art metal tube bending production facility

Our state-of-the-art metal tube bending facility fabricates custom bent metal tube assemblies for leading companies around the world. We have the engineering expertise, cutting-edge tube bending equipment and industry experience to support your application.

Our tube assembly fabrication facilities are your source for both small and large production runs of custom metal tube assemblies in copper, carbon steel and stainless steel, plus hose/tube combos.

High-volume tube assembly production

Our highly trained technicians utilize CNC tube benders, special small manual benders, brazing equipment, flaring and flanging machines and tools, plus custom-engineered and custom-built specialty tube prep machines to produce tube assemblies to your exact specifications. We can fabricate production runs of quality tube assemblies from 3/16" to 1½" in diameter at astonishingly low prices.

MFCP employs only the best production experts in the industry so your tube assemblies are fabricated precisely to your specifications every time.

Our metal tube bending expertise combined with cutting-edge technology allows us to:

- Measure tubes for precision uniformity

- Maintain exact tolerances

- Reverse engineer tube assemblies

- Duplicate customer-furnished tube assemblies

To ensure that all tube assemblies comply with our customers' specifications, we employ a Romer Stinger II inspection arm. This portable inspection tool allows tube fabricators to use the machine’s “hand like” forked wand to follow the centerline path of a bent tube and record the three dimensional data points of even the most complicated tube assembly.

The process is so fast and accurate that the first tube assembly’s data can be used to edit CNC bender instructions - quickly improving the accuracy of the next tube assembly to be fabricated.

The Romer Arm ensures the accuracy of tube bending at Motion & Flow Control Products, Inc. Can we improve your product with steel or stainless steel bent tube assemblies?

Tube bending engineering services

Our engineering team provides complete product design support. We collaborate with our customers to develop a solution that will meet their exact requirements.

From streamlining a bent tube product, recommending changes that will ensure enhanced performance, to developing a prototype for a unique application, our goal is to provide our customers with the support that they need. We produce tube assemblies from virtually any document:

- Hand drawn sketches

- Engineering diagrams

- 3-D XYZ coordinates

- Or we can reverse engineer existing tube assemblies

See more information on prototyping.

In-store tube assembly production

Smaller orders of tube assemblies up to 1¼" in diameter can also be fabricated at any of our five ParkerStore Locations.

No order too small

We welcome your business – even single custom tube assembly orders.

Visit any of our stores today.

Tube Assembly Capabilities

- 3/16" to 1½" OD

- Steel

- Stainless steel

- Copper

- Hose/Tube assembly combos