Parker LD | 24° Flareless Shut-Off Valve, PN 40s for Metric Tubing | Parker EO

|

EO fittings are a great choice for leak free connections under various service conditions ranging from sealing high vacuum and small molecule gases, to high-pressure hydraulic fluids. EO fittings’ compact design makes them ideal for plumbing applications in limited or tight space. EO fittings are suitable for applications in subzero as well as elevated temperatures. The exact service temperature rating is determined by the choice of fitting material, and since EO fittings can be manufactured from a wide range of metals, it's compatibility with various fluids, temperatures, and atmospheric conditions is virtually limitless. |

|

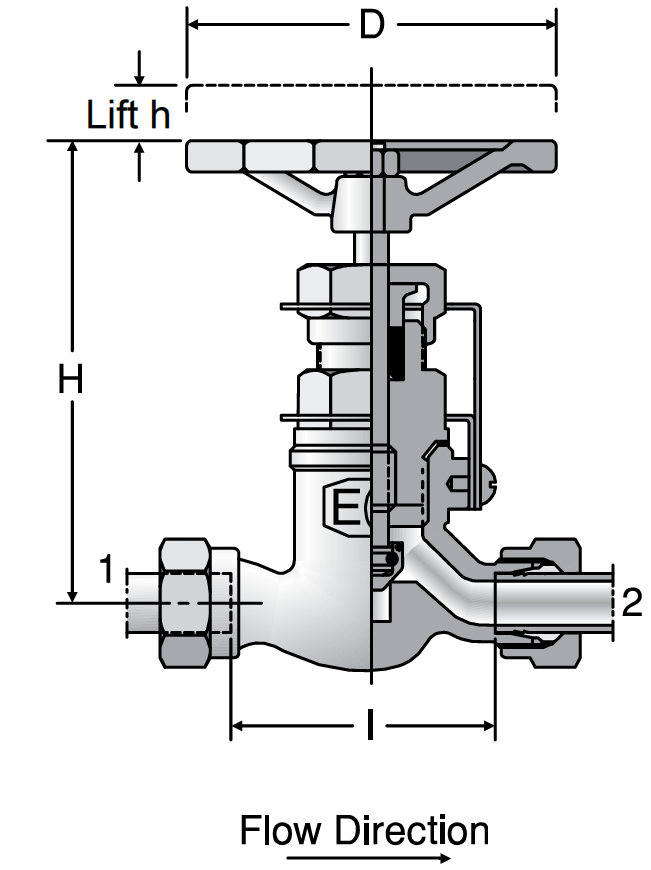

Bite-Type Part #: LD

24° Flareless / 24° Flareless |

|

TUBE |

END |

DN |

D |

h |

H |

I |

Pressure |

|

1 & 2 |

EO |

||||||

|

MS |

|||||||

|

LD10S |

10 |

6 |

63 |

7 |

98 |

45 |

40 |

|

LD12S |

12 |

8 |

63 |

7 |

98 |

49 |

40 |

|

LD14S |

14 |

10 |

63 |

7 |

98 |

54 |

40 |

|

LD16S |

16 |

12 |

80 |

9 |

110 |

67 |

40 |

|

LD20S |

20 |

16 |

80 |

9 |

110 |

69 |

40 |

|

LD25S |

25 |

20 |

100 |

12 |

129 |

86 |

40 |

|

LD30S |

30 |

25 |

100 |

12 |

129 |

93 |

40 |

|

LD38S |

38 |

32 |

100 |

12 |

158 |

108 |

40 |

Note: The pressure specification PN for hand operated shut-off valves applies to the design factor 1.5 (according to DIN 3230 T5 and ISO 5208). Omit "MS" in the part number for brass material

Tube Fittings

- Select another EO Fitting

- Select EO-2 Fitting (Bite type with elastomeric seal for metric tubing)

- Select Ferulok Fitting (Bite type for inch tubing)

- Select Intru-Lok Fitting (Bite type fitting for brass, copper, aluminum and plastic inch tubing)

- Select Another Tube Fitting Type

- Go To Product Selection Page

24° Flareless | Parker EO

The EO fittings are the most widely used bite type fittings in the world.

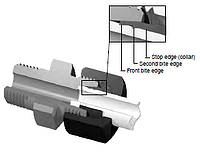

The EO progressive ring fitting is a flareless fitting for metric tubing that consists of a body, a progressive ring (ferrule) and a nut. On assembly, two cutting edges of the progressive ring “bite” into the outer surface of the tube ensuring the necessary holding power and seal for high operating pressures.

The EO Body. EO fitting bodies are available in over thirty configurations. The shaped products (i.e., elbows, tees, crosses) are hot forged, then machined to the stringent EO fitting specifications. The forging process used by Parker further improves the strength and metallurgical properties of the fitting material.