9A Series | Parker Standard Metal Hose

- Hydroforming process maintains a more consistent tube wall thickness and a smoother finish compared to competitive mechanical forming methods

- Brightly annealed tube material used in hydroforming minimizes risk of Corrosion Crevice Cracking failure and increases chemical resistance

- High percentage braid coverage means improved life cycle and protection against core tube damage

- Suitable for vacuum applications to 30 in Hg

- Temperature range for petroleum-based hydraulic fluids of -380º F to +1200º

|

9A Metal Hydraulic HoseApplication: Hot oil lines, petrochemical, power generation, pulp & paper, chemical transfer, solvent and steam lines |

9A Metal Hose Sizes and Performance Specifications

| ID (in) |

# of Braids |

OD (in) |

Min. Bend Radius (in) |

Working Pressure (PSI) |

Burst Pressure (PSI) |

Weight Per ft (lb) |

| 1/4 | 0 | 0.41 | 4.5 | 90 | 0.04 | |

| 1 | 0.47 | 1800 | 7233 | 0.11 | ||

| 2 | 0.53 | 2700 | 9100 | 0.18 | ||

| 3/8 | 0 | 0.65 | 5.0 | 70 | |

0.10 |

| 1 | 0.71 | 1186 | 6230 | 0.20 | ||

| 2 | 0.77 | 2336 | 9345 | 0.30 | ||

| 1/2 | 0 | 0.77 | 5.5 | 70 | |

0.11 |

| 1 | 0.83 | 1186 | 4743 | 0.22 | ||

| 2 | 0.89 | 1779 | 7115 | 0.33 | ||

| 5/8 | 0 | 0.96 | 7.0 | 57 |

|

0.17 |

| 1 | 1.02 | 1205 | 4820 | 0.33 | ||

| 2 | 1.08 | 1808 | 7230 | 0.49 | ||

| 3/4 | 0 | 1.16 | 8.0 | 43 | 0.19 | |

| 1 | 1.22 | 898 | 3591 | 0.37 | ||

| 2 | 1.28 | 1347 | 5387 | 0.55 | ||

| 1 | 0 | 1.47 | 9.0 | 43 | |

0.26 |

| 1 | 1.53 | 718 | 2872 | 0.50 | ||

| 2 | 1.59 | 1077 | 4308 | 0.74 | ||

| 1 1/4 | 0 | 1.75 | 10.0 | 43 | |

0.29 |

| 1 | 1.83 | 645 | 2581 | 0.61 | ||

| 2 | 1.91 | 968 | 3872 | 0.93 | ||

| 1 1/2 | 0 | 2.08 | 11.0 | 28 | |

0.47 |

| 1 | 2.16 | 531 | 2125 | 0.85 | ||

| 2 | 2.24 | 797 | 3188 | 1.23 | ||

| 2 | 0 | 2.61 | 13.0 | 14 | |

0.59 |

| 1 | 2.69 | 449 | 1797 | 1.11 | ||

| 2 | 2.77 | 674 | 2696 | 1.63 | ||

| 2 1/2 | 0 | 3.40 | 0.84 | |||

| 1 | 3.50 | 16.0 | 1669 | 1.64 | ||

| 2 | 3.60 | 2504 | 2.44 | |||

| 3 | 0 | 3.88 | 1.18 | |||

| 1 | 3.98 | 18.0 | 1384 | 2.06 | ||

| 2 | 4.08 | 2076 | 2.94 | |||

| 4 | 0 | 4.96 | 1.41 | |||

| 1 | 5.06 | 22.0 | 1194 | 2.69 | ||

| 2 | 5.16 | 1791 | 3.97 | |||

| 5 | 0 | 6.00 | 2.18 | |||

| 1 | 6.12 | 28.0 | 1099 | 3.61 | ||

| 2 | 6.24 | 1649 | 5.04 | |||

| 6 | 0 | 7.01 | 2.69 | |||

| 1 | 7.13 | 32.0 | 839 | 4.44 | ||

| 2 | 7.25 | 1259 | 6.19 |

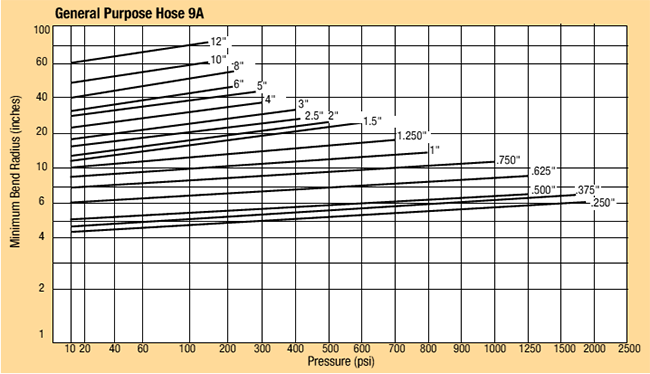

Pressure Rating vs. Minimum Bend Radius of Parker 9A Flexible Metal Hoses

The minimum bend radius of flexible metal hoses increases with pressure. Bend radius is measured from the center line of the hose, and pressure is measured at an ambient temperature of 70°F.

Inside diameter (in inches) of each metal hose is indicated next to the corresponding curve.

9A Metal Hose Assembly Part Number Nomenclature

Part Number 9A1TU01060606C-30 explained

9A = Hose series

- 9A = General Purpose

- 9M = Flexible

- 9H = High Pressure (obsoleted)

- 9P = High Pressure (higher than 9H)

1 = Core/Braid Combination 1. Core/Braid combinations. Choices described below:

- 0 - 321 SS Tube, No Braid

- 1 - 321 SS Tube, 304 SS Single Braid

- 2 - 321 SS Tube, 304 SS Double Braid

- 3 - 316 SS Tube, No Braid

- 4 - 316 SS Tube, 304 SS Single Braid

- 5 - 316 SS Tube, 304 SS Double Braid

- 6 - 321 SS Tube, 316 SS Single Braid

- 7 - 321 SS Tube, 316 SS Double Braid

- 8 - 316 SS Tube, 316 SS Single Braid

- 9 - 316 SS Tube, 316 SS Double Braid

TU01 = Fitting Configurations: Universal Tube Stub on one side, male pipe thread with hex on the other side. The available fitting configurations are below - not all configurations are available in all sizes. Contact us prior to ordering.

- 01 = Male pipe thread with hex (NPTF)

- 02 = Female pipe thread (NPT)

- 06 = Female JIC flare swivel (37°)

- U7 = Female pipe union (NPT)

- TU = Universal tube stub

- JC = Female O-ring face seal swivel (ORFS)

- AL = A-Lok compression®

- 9K = Raised face weld neck, 150 lb fixed flange

- 9Y = Raised face weld neck, 300 lb fixed flange

- 4K = Schedule 40 type A stub, 150 lb lap joint (floating) flange

- 1Y = Schedule 40 type A stub, 300 lb lap joint (floating) flange

- 8K = Raised face 150 lb fixed slip-on flange

- 8Y = Raised Face 300 lb fixed slip-on flange

060606 = ID dash sizes. First end, second end and hose, respectively.

C = Stainless steel material for the hose ends:

- C = 300 series stainless steel

- K = 316 stainless steel

30 = Overall length of the assembly (end-to-end) in inches

How to Order

- Visit One of Our ParkerStores.

- Visit Our eStore.

- Request a Quote.

AVAILABLE HOSE STYLES

Select from the list below to navigate to a specific category...

- Air & general purpose hoses

- Aircraft fuel hoses

- Automotive hoses

- CNG hoses

- Fleet/truck hoses

- Multi-purpose hoses

- Food handling hoses

- Fire supression hoses

- Material handling hoses

- Petroleum dispenser hoses

- Specialty hoses

- Steam hoses

- Welding hoses

- Hose Accessories - Sleeves, shields, whip restraints...