9H Series | Parker High Pressure Metal Hose

Note: Effective June 2018, the 9H Series of Parker High Pressure Metal Hose has been obsoleted and will no longer be available for purchase. Use 9P Series High Pressure Flexible Metal Hose as a replacement.

- Specially designed to maintain extreme pressure and flexibility

- Helical construction is self-draining

- High percentage braid coverage means improved life cycle and protection against core tube damage

- Suitable for vacuum applications to 30 in Hg

- Temperature range for petroleum-based hydraulic fluids of -380º F to +1200º F

- Factory assembly only, no bulk hose sales

|

9H High Pressure Metal Hydraulic HoseApplication: Hot oil lines, petrochemical, power generation, chemical transfer, pulp & paper, solvent and steam lines |

9H Metal Hose Sizes and Performance Specifications

| ID (in) |

# of Braids |

OD (in) |

Min. Bend Radius (in) |

Working Pressure (PSI) |

Burst Pressure (PSI) |

Weight Per ft (lb) |

| 1/4 | 1 | 0.52 | 5.0 | 4,600 | 18,400 | 0.21 |

| 2 | 0.62 | 5,800 | 23,200 | 0.32 | ||

| 5/16 | 1 | 0.62 | 5.1 | 4,000 | 16,000 | 0.29 |

| 2 | 0.74 | 4,800 | 19,200 | 0.45 | ||

| 3/8 | 1 | 0.70 | 5.5 | 3,800 | 15,200 | 0.36 |

| 2 | 0.82 | 4,000 | 16,000 | 0.57 | ||

| 1/2 | 1 | 0.82 | 5.7 | 2,600 | 10,400 | 0.43 |

| 2 | 0.94 | 3,700 | 14,800 | 0.69 | ||

| 5/8 | 1 | 0.97 | 6.1 | 2,400 | 9,600 | 0.51 |

| 2 | 1.09 | 2,700 | 10,800 | 0.82 | ||

| 3/4 | 1 | 1.19 | 6.5 | 2,000 | 8,000 | 0.64 |

| 2 | 1.31 | 2,200 | 8,800 | 1.03 | ||

| 1 | 1 | 1.39 | 7.9 | 1,500 | 6,000 | 0.78 |

| 2 | 1.51 | 2,000 | 8,000 | 1.25 | ||

| 1 1/4 | 1 | 1.75 | 9.4 | 1,100 | 4,400 | 1.15 |

| 2 | 1.87 | 1,600 | 6,400 | 1.70 | ||

| 1 1/2 | 1 | 2.07 | 12.2 | 1,000 | 4,000 | 1.45 |

| 2 | 2.19 | 1,500 | 6,000 | 2.16 |

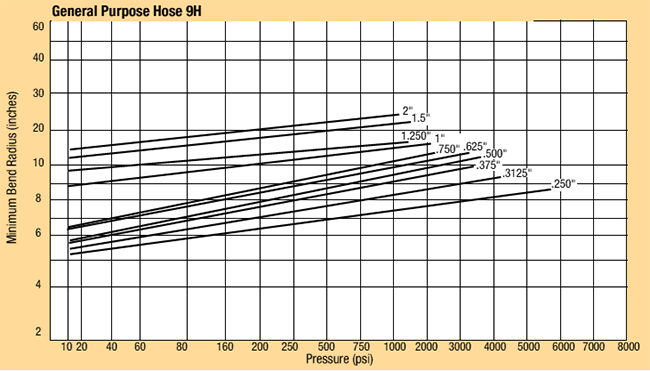

Pressure Rating vs. Minimum Bend Radius of Parker 9H Flexible Metal Hoses

The minimum bend radius of flexible metal hoses increases with pressure. Bend radius is measured from the center line of the hose, and pressure is measured at an ambient temperature of 70°F.

Inside diameter (in inches) of each metal hose is indicated next to the corresponding curve.

9H Metal Hose Assembly Part Number Nomenclature

Part Number 9H1TU01060606C-30 explained

| 9H | 1 | TU | 01 | 06 | 06 | 06 | C | - | 30 |

9H = Hose series

- 9A = General Purpose

- 9M = Flexible

- 9H = High Pressure

- 9P = High Pressure (higher than 9H)

- 0 - 321 SS Tube, No Braid

- 1 - 321 SS Tube, 304 SS Single Braid

- 2 - 321 SS Tube, 304 SS Double Braid

- 3 - 316 SS Tube, No Braid

- 4 - 316 SS Tube, 304 SS Single Braid

- 5 - 316 SS Tube, 304 SS Double Braid

- 6 - 321 SS Tube, 316 SS Single Braid

- 7 - 321 SS Tube, 316 SS Double Braid

- 8 - 316 SS Tube, 316 SS Single Braid

- 9 - 316 SS Tube, 316 SS Double Braid

TU01 = Fitting Configurations: Universal Tube Stub on one side, male pipe thread with hex on the other side. The available fitting configurations are below - not all configurations are available in all sizes. Contact us prior to ordering.

- 01 = Male pipe thread with hex (NPTF)

- MT = Male pipe thread without hex (NPT)

- 02 = Female pipe thread (NPT)

- 03 = Male JIC flare (37°)

- 06 = Female JIC flare swivel (37°)

- 07 = Female pipe swivel

- U7 = Female pipe union (NPT)

- TU = Universal tube stub

- JC = Female O-ring face seal swivel (ORFS)

- AL = A-Lok compression®

- HV - Male VacuSeal™

- P6 = CPI™ compression

- Q1 = UltraSeal™ swivel

- VH = Female VacuSeal™

060606 = ID dash sizes. First end, second end and hose, respectively.

C = Stainless steel material for the hose ends:

- C = 300 series stainless steel

- K = 316 stainless steel

30 = Overall length of the assembly (end-to-end) in inches.

How to Order

- Visit One of Our ParkerStores.

- Visit Our eStore.

- Request a Quote.

AVAILABLE HOSE STYLES

Select from the list below to navigate to a specific category...

- Air & general purpose hoses

- Aircraft fuel hoses

- Automotive hoses

- CNG hoses

- Fleet/truck hoses

- Multi-purpose hoses

- Food handling hoses

- Fire supression hoses

- Material handling hoses

- Petroleum dispenser hoses

- Specialty hoses

- Steam hoses

- Welding hoses

- Hose Accessories - Sleeves, shields, whip restraints...