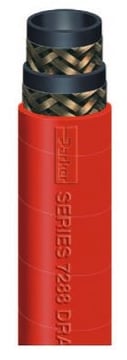

Steam Industrial Hoses | Parker | DRAGON BREATH® 250 Oil Resistant Steam Hose | 7288 Series

|

Series 7288 is a traditional oil resistant hose designed for long-lasting steam service - one of the toughest applications for hose, where the hot-cold/wet-dry cycling attacks rubber compounds externally as well as internally. The hose construction incorporates an EPDM tube that resists heat and popcorning, and a wire braid reinforcement for crush-resistant durability, kink resistance, and a path to conduct a static electrical charge to ground. The red chloroprene cover is resistant to weathering and oil - an important criteria for oil refineries and petrochemical plants - and provides color-coded identification.

|

|

Part # |

ID (in) | Reinf Braids |

OD (in) | Min Bend Rad (in) | Max Rec WP (psi) | Perm Cplg Rec* |

| 7288-502 | 1/2 | 2 | 1.031 | 7.0 | 261 | 43 |

| 7288-752 | 3/4 | 2 | 1.343 | 9.5 | 261 | CS, 43 |

| 7288-1002 | 1 | 2 | 1.594 | 12.0 | 261 | CS, 43 |

*Couplings: Refer to CrimpSource at www.safehose.com for coupling recommendations and crimp specifications.

WARNINGS

Water changes to hot water and phases of steam when subjected to heat and pressure. The greater the pressure, the higher the temperature required to acheive and maintain a steam phase. If steam escapes, dangerous quantities may be released very suddenly. Exposure to hot water, low pressure steam and high pressure steam may cause severe scalding and fatal burns.

Use only hoses designated for steam service for steam applications.

Prior to use with detergents or rust inhibitors, refer to the chemical guide in the Parker Industrial Hose catalog.

Drain steam hose after each use to reduce the possibility of hose popcorning while in service.

How to Order

- Visit One of Our ParkerStores.

- Visit Our eStore.

- Request a Quote.

Steam Hoses

- DRAGON BREATH® II Chlorobutyl Barber Pole Steam Hose - 7285

- STEAM-LANCE® 250 EPDM Compact Steam Hose - 7263C & 7264C

- STEAM-LANCE® 250 EPDM Steam Hose - 7263(E) & 7264

- DRAGON BREATH® 250 Oil Resistant Steam Hose - 7288

- DRAGON BREATH® Chlorobutyl Compact Steam Hose - 7286C

- MPW-1000® High Pressure Wire Braid Multipurpose Hose - 7204

- Hydrocarbon Drain Hose - 7200

- Large Bore Hydrocarbon Drain Hose - 7200LB

AVAILABLE HOSE STYLES

Select from the list below to navigate to a specific category...

- Air & general purpose hoses

- Aircraft fuel hoses

- Automotive hoses

- CNG hoses

- Fleet/truck hoses

- Multi-purpose hoses

- Food handling hoses

- Fire supression hoses

- Material handling hoses

- Petroleum dispenser hoses

- Specialty hoses

- Steam hoses

- Welding hoses

- Hose Accessories - Sleeves, shields, whip restraints...