Parker Cylinders used in Hybrid Actuation Systems for Solar Tracking Applications | HAS-RDH

Parker HAS-RDH are hybrid (electromechanical and hydraulic) actuation systems specifically designed for solar tracking applications. They combine the fine control of electromechanical actuators with the power density, longer life, and resistive force of a traditional hydraulic system. They are well suited for both mobile and industrial linear motion applications.

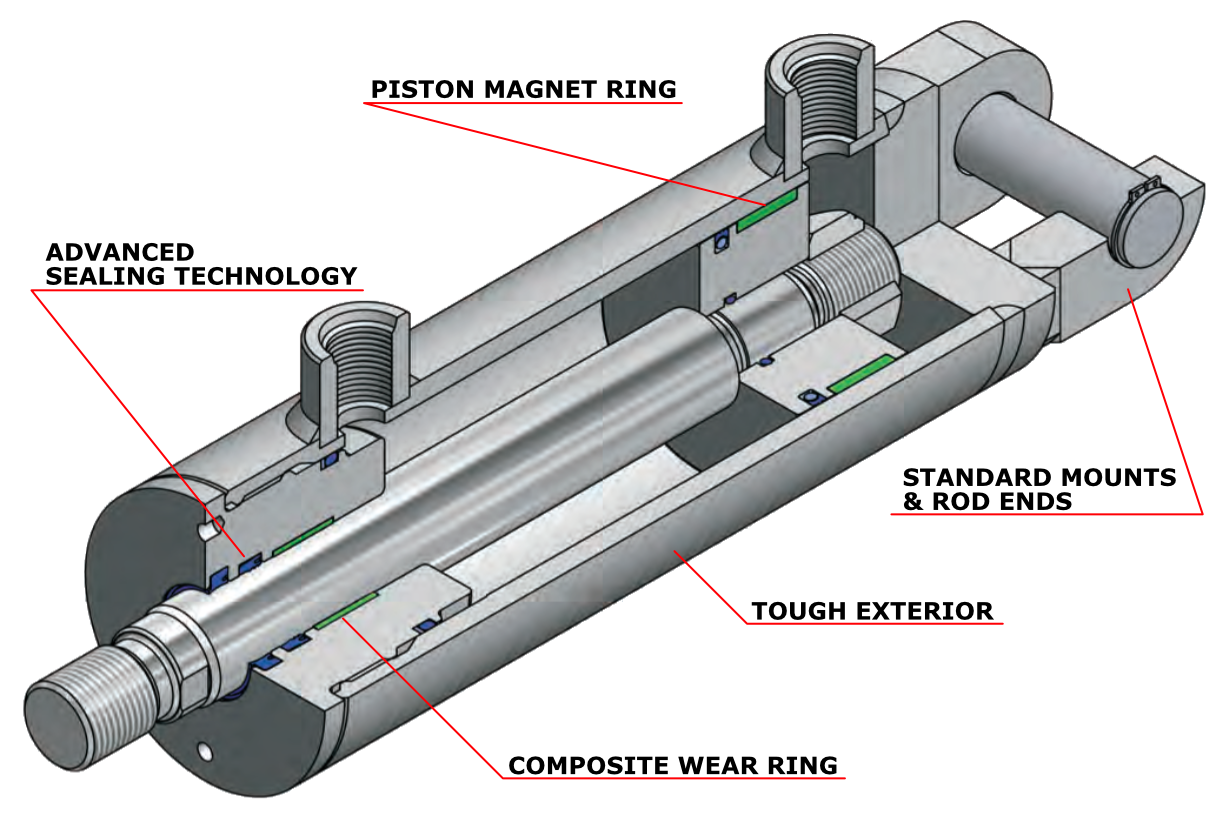

HAS-RDH Cylinder Description

Piston Magnet Ring

- Parker ALS switch ready with piston magnet ring. (Parker ALS switch is the lowest cost point feedback solution for carbon steel cylinders.)

- Switches can be located anywhere along the stroke and in any orientation

- Round body

Advanced Sealing Technology

- Tri-lip rod seal (3 sealing edges!) and bi-directional piston seal feature proven leak-free performance

- Durable polyurethane material is used to maximize seal life

- Nitrile end seals and backup rings on a smooth bore of the cylinder body for optimal sealing and elimination of extrusion problems

- Composite rod and piston wear rings are internally lubricated for reduced friction and formulated for heavy-duty, load-bearing applications

- Standard rod material is case-hardened, hard chrome plated and polished to an optimum finish

- And since we make our own seals, all seals have immediate availability in other popular compounds

Mounts & Rod Ends

Standard mounts and rod ends accommodate commercially-available NFPA accessories for easy installation.

Tough Exterior

- Steel cap, cylinder body and ports for high-strength in rough environments

- Case-hardened, hard chrome plated and polished carbon steel piston rod for damage resistance, long rod seal life and low friction

- Outboard urethane rod wiper seal to remove external debris and adherents from the piston rod

- High quality paint coating for interior or exterior applications.

- Global Shield Corrosion Resistance Coating available for extreme environments

Composite Wear Ring

- Heat stabilized and internally lubricated for low friction and maximum service life in any application

- Strength characteristics meet or exceed most metals traditionally used in wear rings

- Parker WearGard™ bearing materials are backed by over 30 years of manufacturing expertise