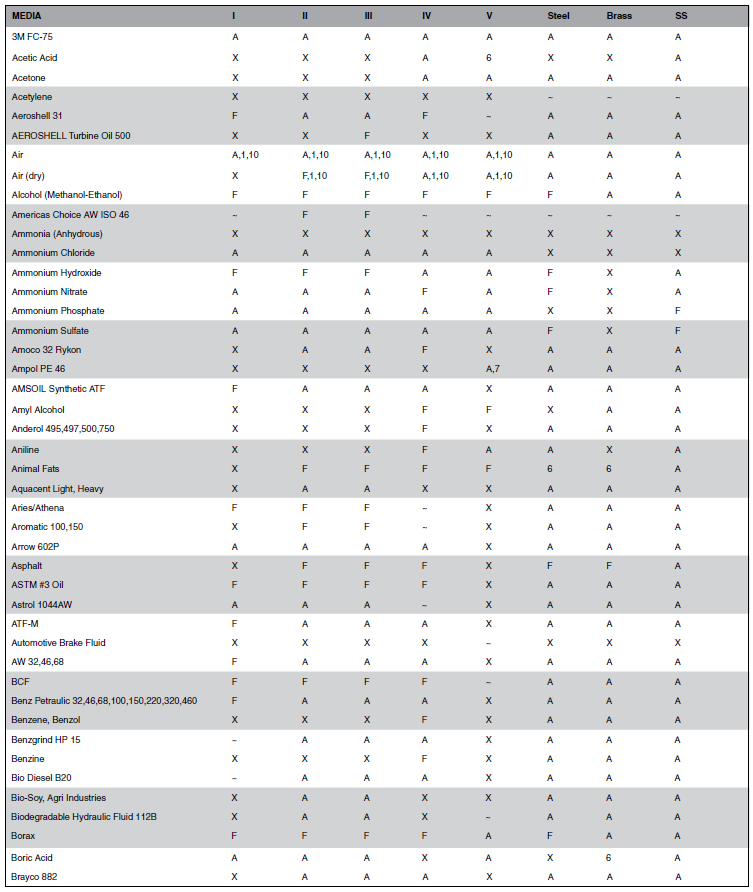

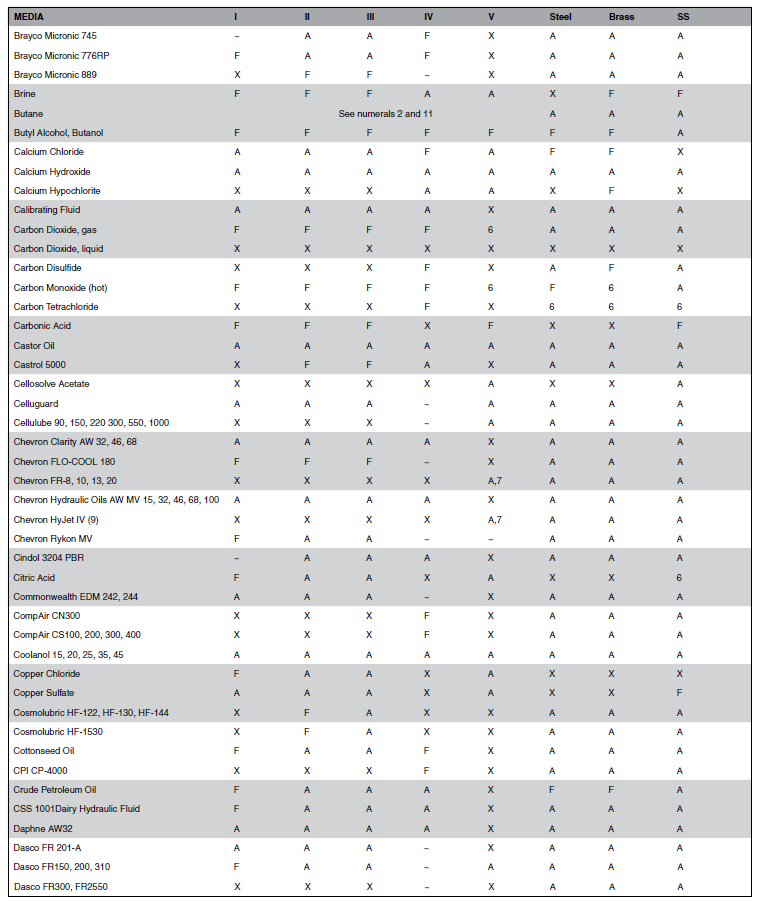

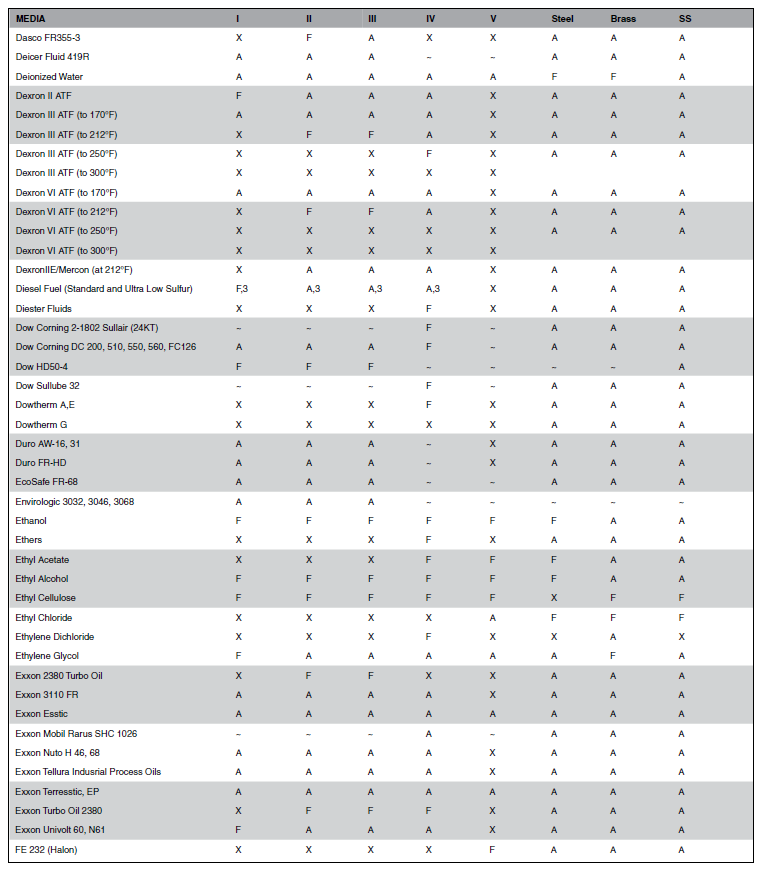

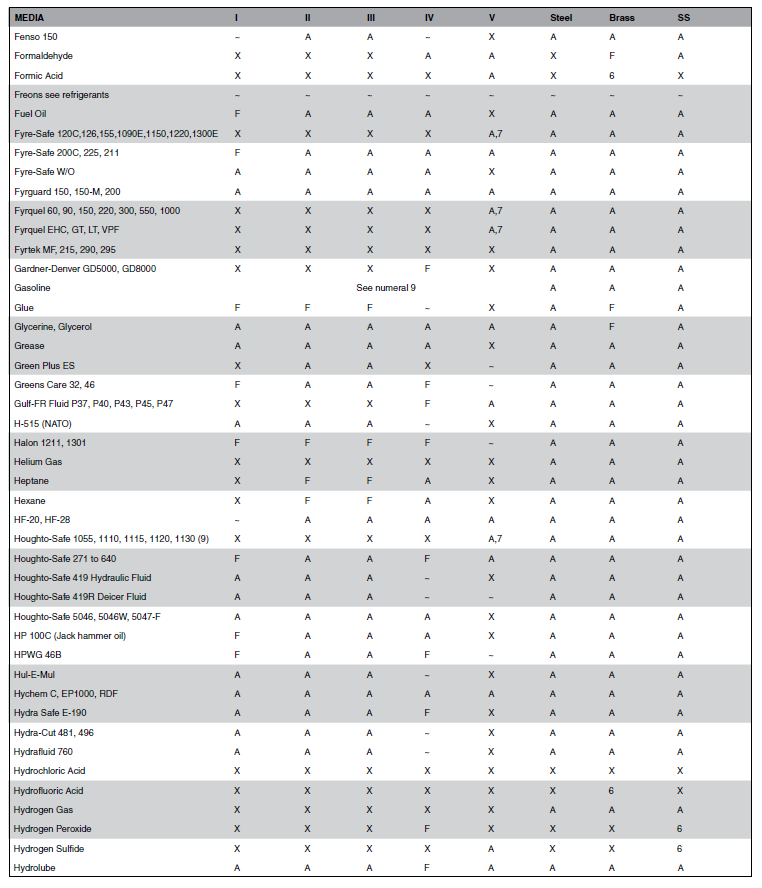

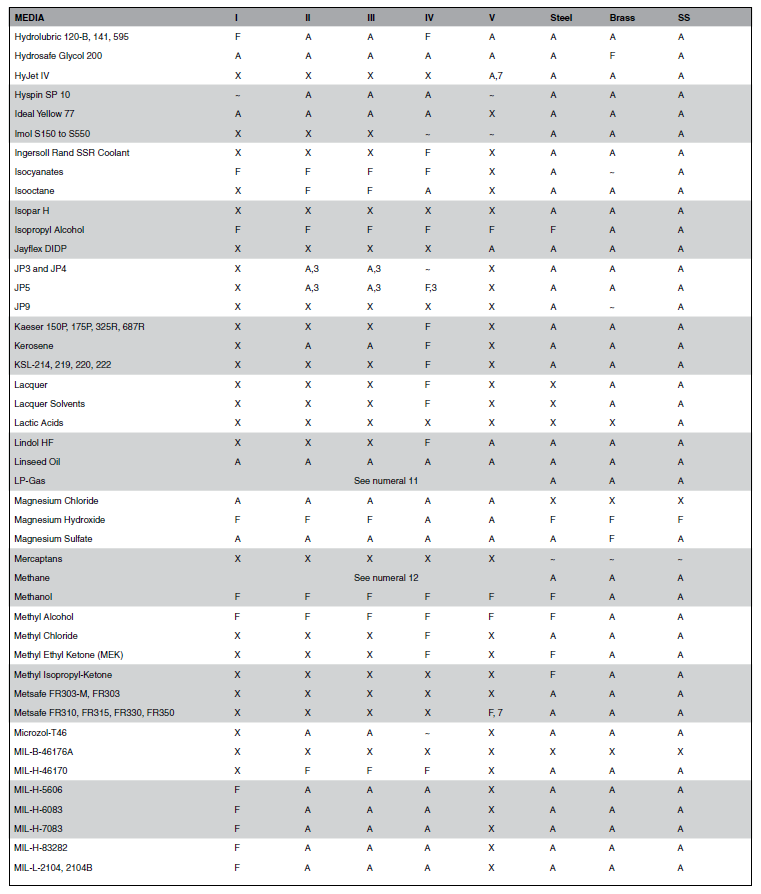

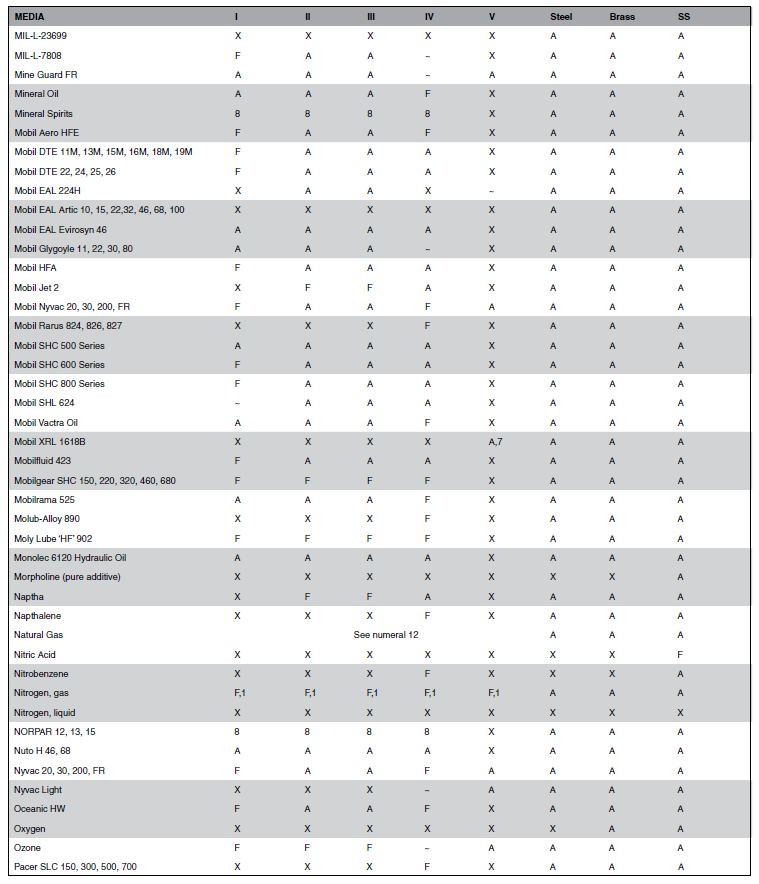

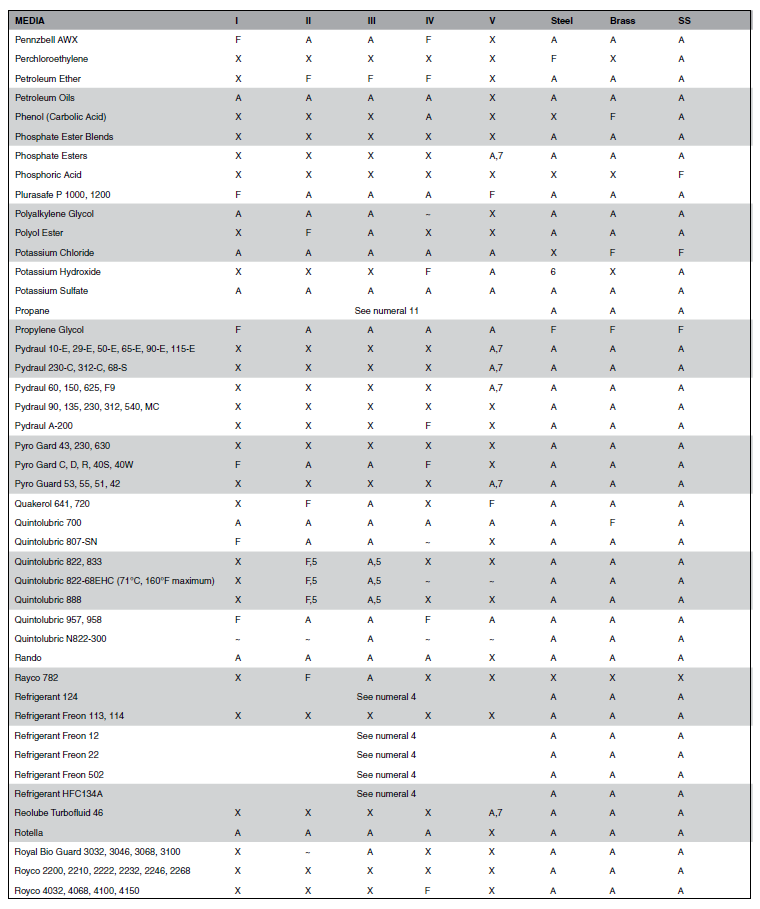

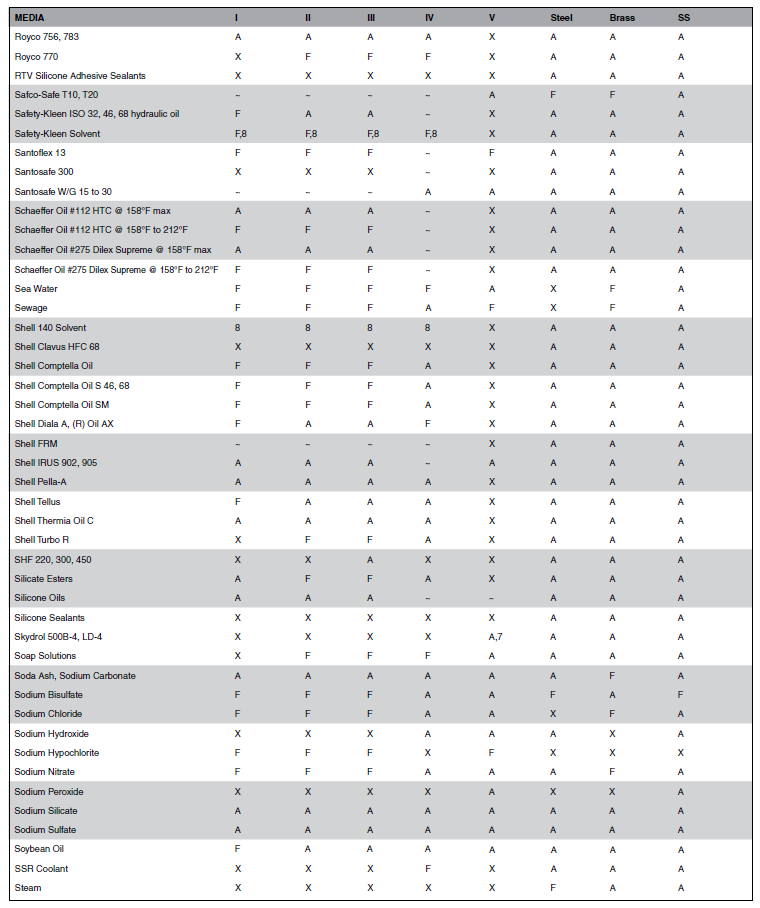

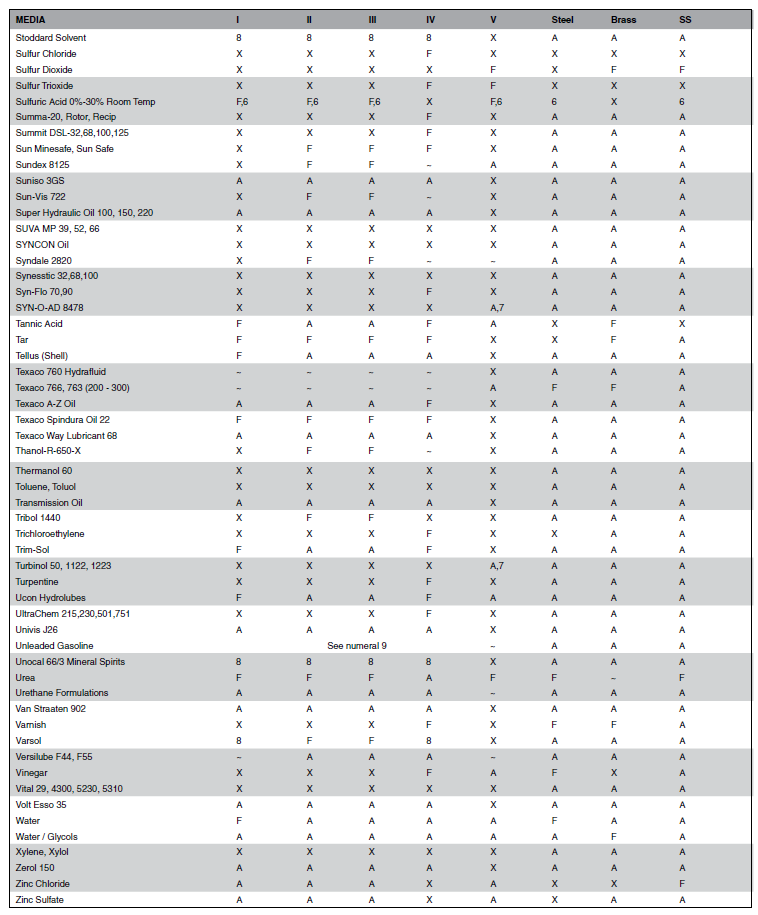

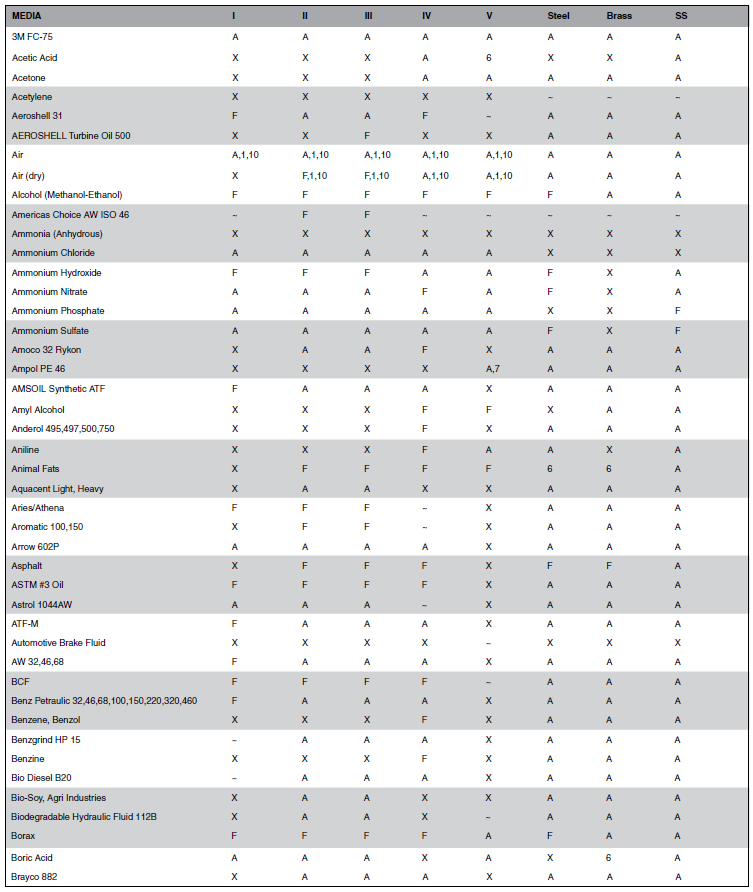

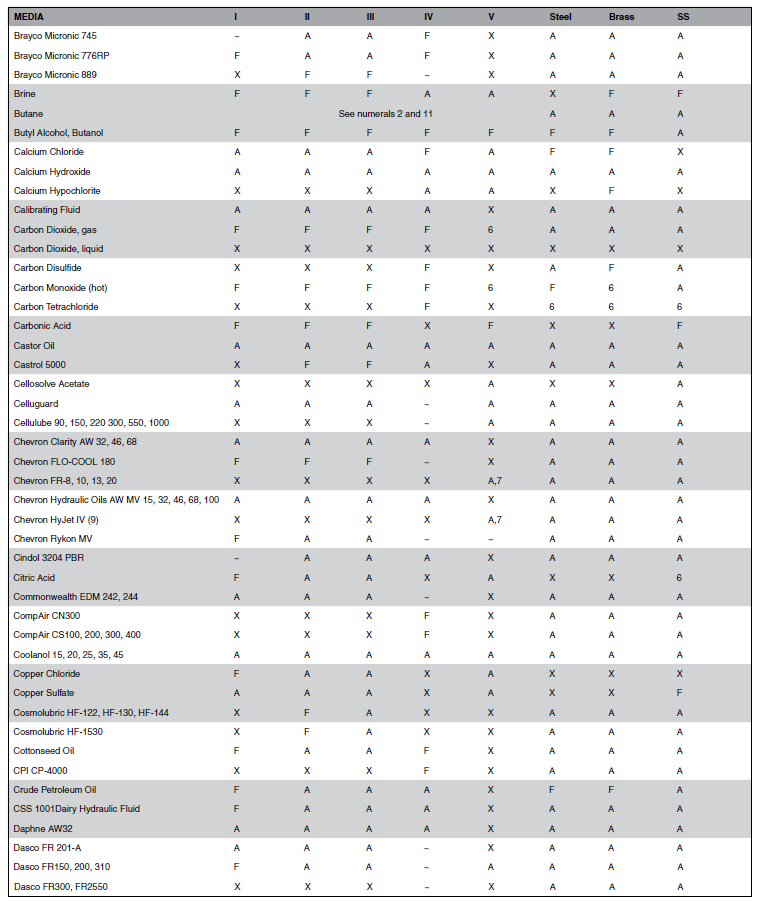

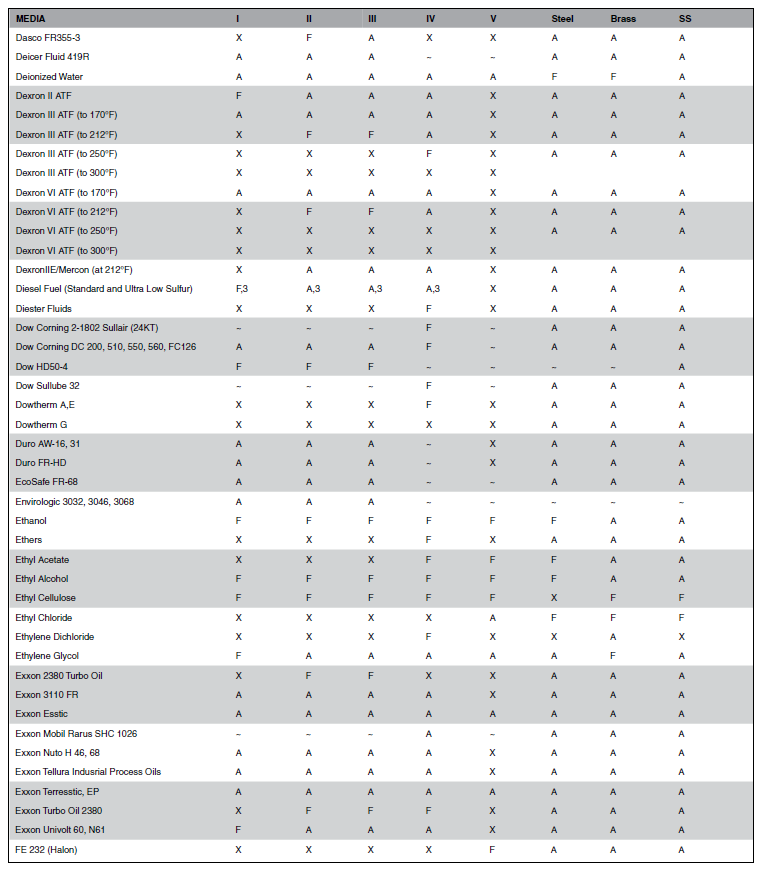

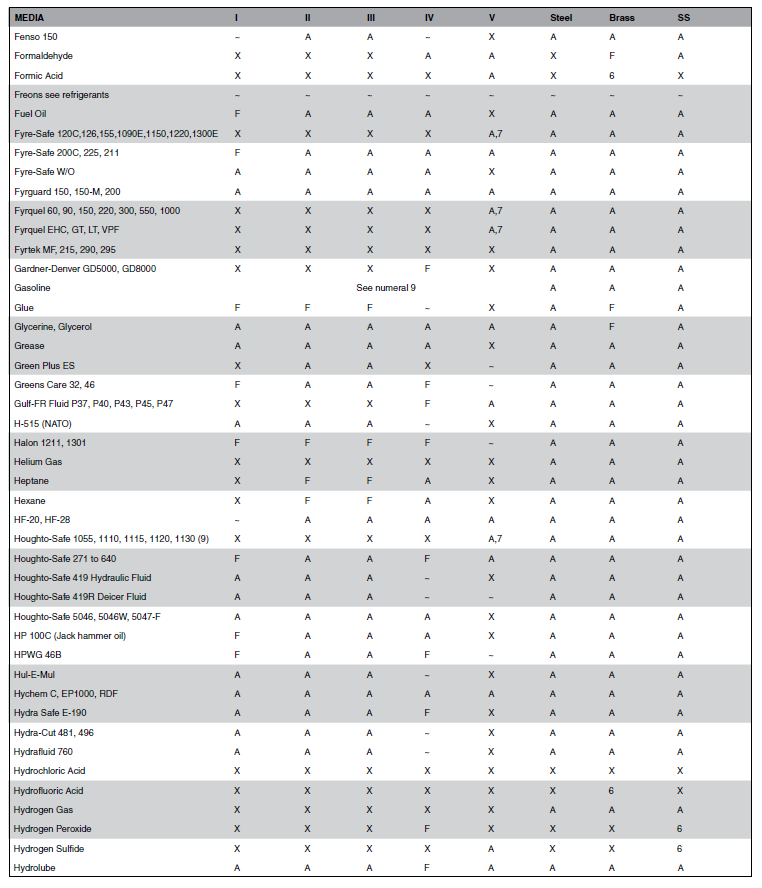

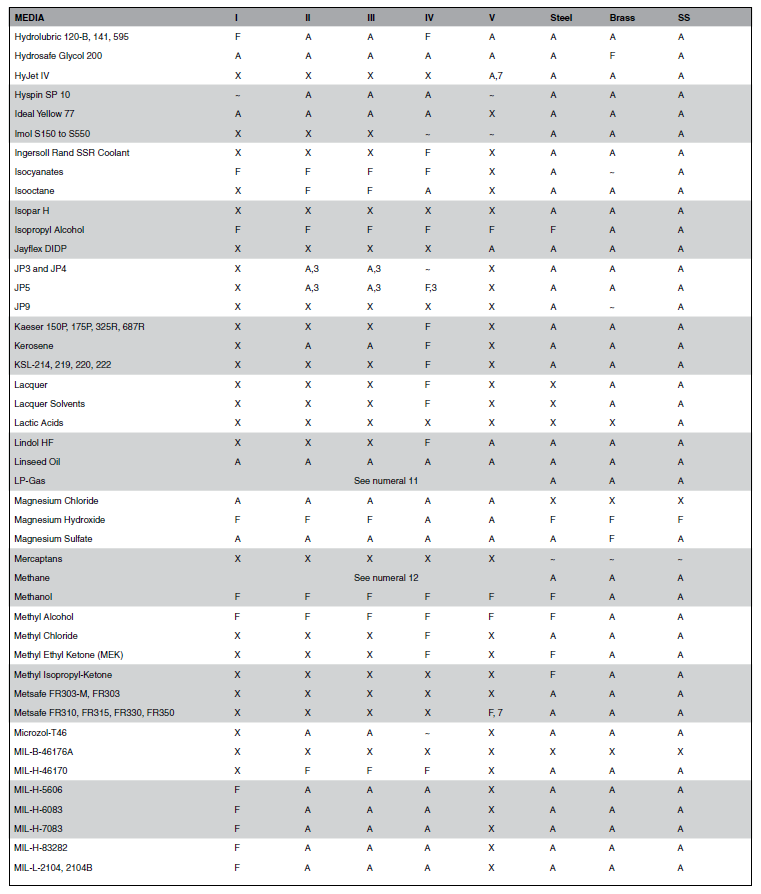

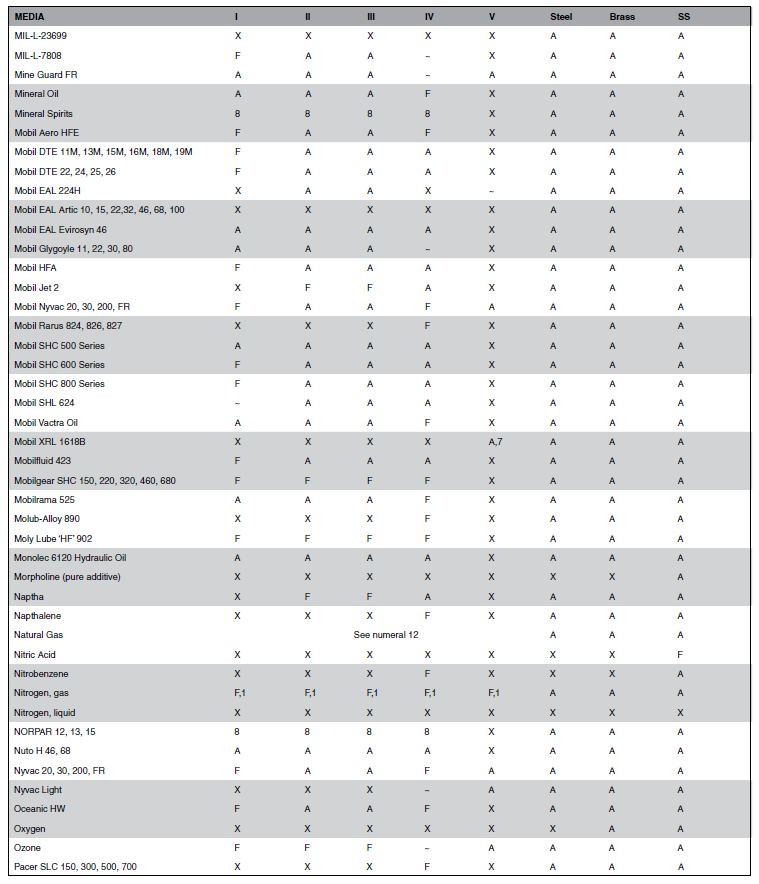

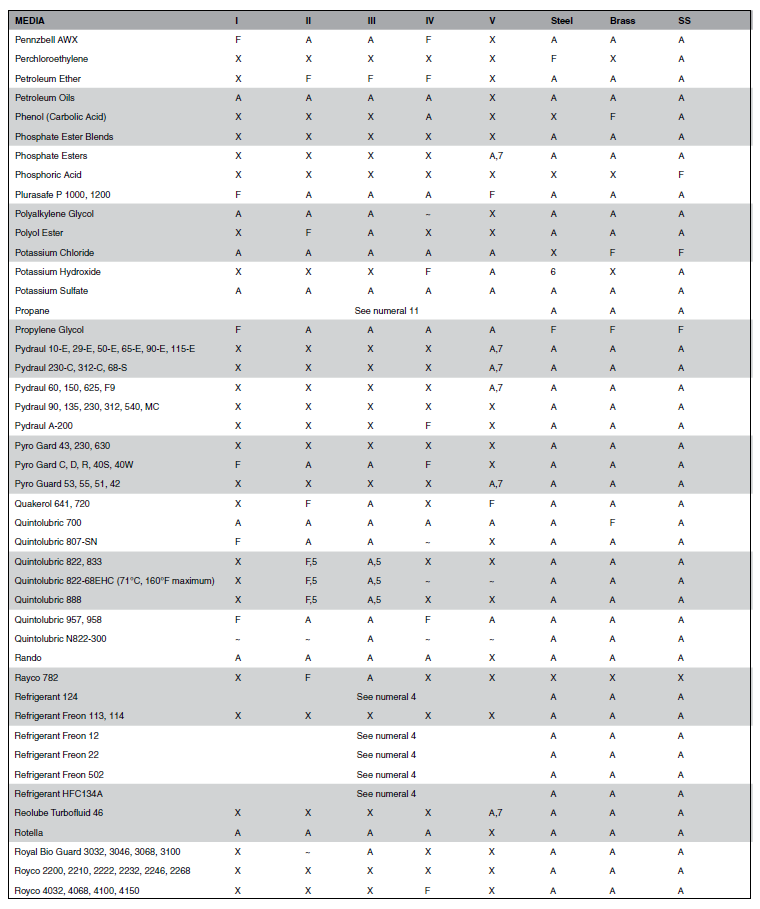

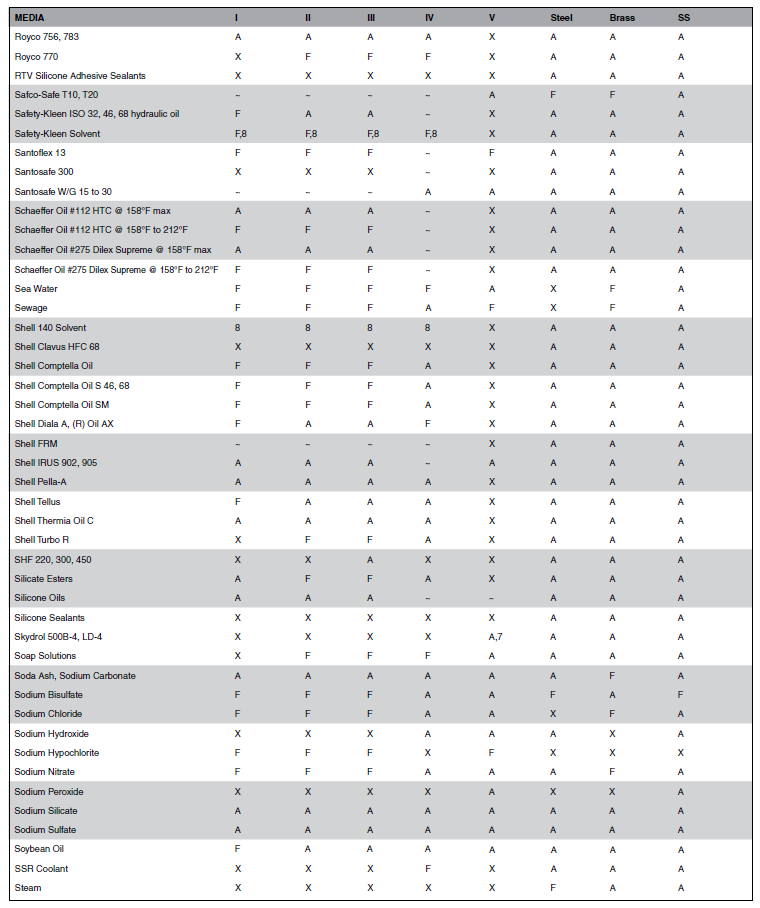

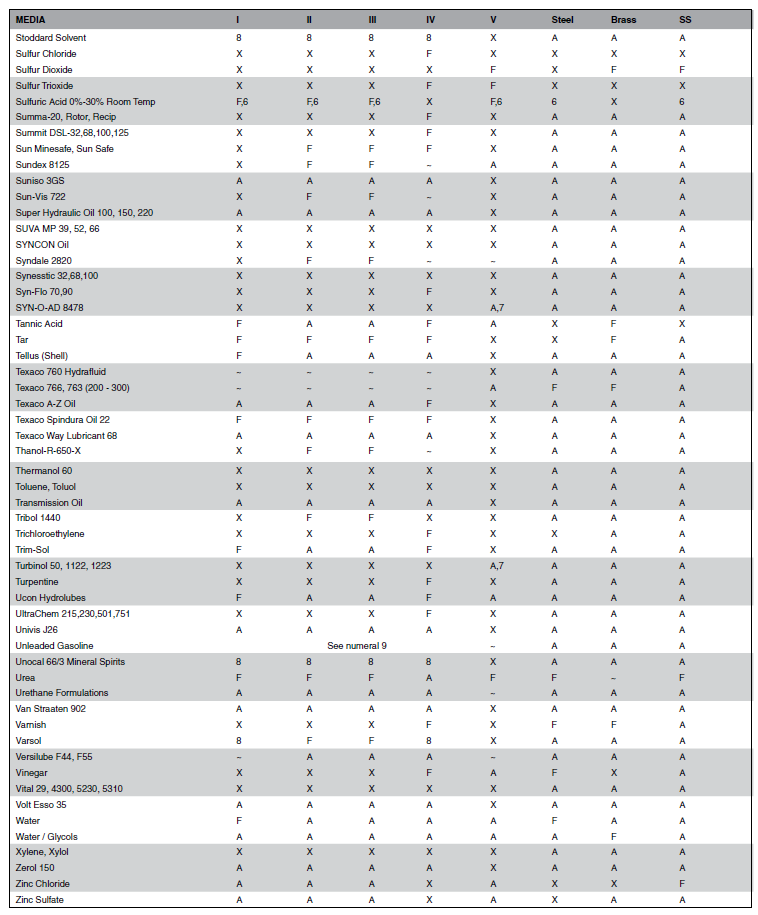

Chemical Compatibility for Parker Rubber Cover Hydraulic Hose

The information below covers the chemical compatibility of hoses, which can also be found in Parker Catalog 4400, Edition 2/2015 (Rubber Hose). This chemical compatibility guide must not be used in conjunction with any other compatibility guides from previous or future catalog editions, bulletins, or publications. Incorrect use of these charts could result in personal injury, death or property damage.

Hose Selection by Medium and Hose Type

This hose compatibility chart is a reference for Parker hose compatibility with various fluid media. It is intended as a guide to chemical compatibility with inner tube materials and assembly lubricant applied internally. The specific recommendations are based upon field experience, the advice of various polymer or fluid suppliers, and specific laboratory experiments. It must be stressed, however, that this information is offered only as a guide.

Final hose selection depends also upon pressure, fluid temperature, ambient temperature, and special requirements or variations, which may not be known by Parker Hannifin or Motion & Flow Control Products, Inc.. Legal and other regulations must be followed with particular care. Where an external compatibility problem may occur, or for fluids not listed, we encourage you to first contact the fluid manufacturer for a recommendation prior to contacting Motion & Flow Control Products, Inc.. or the Technical Service Department, Hose Products Division, Wickliffe, Ohio.

How to Use the Chart

- Locate medium to be carried using the Chemical Resistance Table on the following pages.

- Select suitability of hose and fitting material from the table based on the letter rating in the table. See resistance rating key below for an explanation of compatibility ratings. See the Numerals Key below for an explanation when a numeral, or a numeral and a letter rating are present in the table.

- The Column headings on the Chemical Resistance Table, I, II, III, IV, V, refer to specific groups of hoses.

- Locate hose part number under Column l, ll, III, IV, V from the list below.

- For fitting material availability refer to appropriate fitting section of the Catalog 4400.

- Check hose specifications in the Catalog 4400. Contact Hose Division

Resistance Rating Key

All data based on 70°F unless otherwise noted.

A = Preferred, good to excellent with little or no change in physical properties.

F = Fair, marginal or conditional with noticeable affects on physical properties.

X = Unsuitable, severe affects on physical properties.

~ = No rating, insufficient information.

Numerals Key

- For air or gaseous applications above 250 PSI (1,7 MPa), the cover should be pin pricked. The service life for air or gaseous applications can be unpredictable, especially at higher pressures. Contact Parker Technical Service Department for more information.

- Legal and insurance regulations must be considered. Contact Technical Service Department for more information.

- Push-Lok hoses 801 and 836 are approved for diesel fuel applications only when coupled with HY series fittings.

- Use 285, 235 or 244 hoses. The compatibility of the systems refrigeration oil with these hoses needs to be evaluated on a case by case basis. Contact Parker Hose Product Technical Service Department for more information. Do not use mineral oil or Alkyl Benzene refrigeration oils with 244 hose. Chemical compatibility does not imply low permeation.

- 150°F (65°C) maximum.

- Satisfactory at some concentrations and temperatures, unsatisfactory at others.

- For phosphate ester fluids use 304, 424, 774, F42 or 804 hoses.

- Acceptable for flushing hose assemblies.

- 221FR hose recommended.

- For dry air applications, hoses with inner tubes from columns IV, and V are preferred. See hose specifications for maximum recommended temperatures with air.

- Use SS23CG or SS25UL

- Use SS23CG

Hose Types

- Column I: AX, BXX, P35, 201, 341, 601, 701, 711, 721, 721TC, 721ST, 731, 761, 781, 791TC, 881

- Column II: SS25UL, 301LT, 351TC, 351ST, 421WC, 431, 451TC, 451ST, 471TC, 471ST, 472LT, 722LT, 772LT, 792LT, 801, 811, 811HT

- Column III: JK, 221FR, 302, 387, 422, 472TC, 482TC, 482ST, 487, 722TC, 772TC, 772ST, 782TC, 782ST, 787TC, 792TC, 792ST, 797TC, 821

- Column IV: 206, 213, 266, 293, 426, 611HT, 821FR, 836, 436

- Column V: F42, 304, 424, 774, 804

Caution:

The fluid manufacturer’s recommended maximum operating temperature for any specific name-brand fluid should be closely observed by the user. Specific name brand fluids can vary greatly between manufacturers even though they are considered to be from the same family or type of fluids. Using fluids above the manufacturers maximum recommended temperature can cause the fluid to break down, creating by-products that can be harmful to elastomers or other materials used in the system. When selecting a hose type, both the fluid manufacturer and hose manufacturers maximum temperature limit must be taken into consideration, with the lower of the two taking precedence.

Chemical Compatibility Tables