Parker Flange Connection Assembly & Installation

Flange Connection Advantages

Large threaded port connections, such as SAE straight thread, require very high torque to assemble. This makes assembly very difficult, especially where wrench clearance is limited. Flange connections solve this problem by dividing the hydraulic load among four bolts each requiring much less torque, smaller wrenches and smaller wrench clearance.

6 Steps of Proper Flange Port Assembly

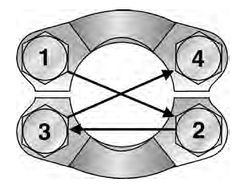

Steps to properly assemble the flange port clamping bolts:

|

Flange Bolt Tightening Sequence |

| CODE 61 FLANGE RECOMMENDED BOLT TORQUE VALUES | ||||

| Size (in) |

Inch Bolt J518 |

Torque +10% -0 (ft-lb) |

Metric Bolt ISO 6162 |

Torque +10% -0 (N-m) |

| 1/2 | 5/16 - 18 | 17 | M8 | 24 |

| 3/4 | 3/8 - 16 | 31 | M10 | 50 |

| 1 | 3/8 - 16 | 31 | M10 | 50 |

| 1 1/4 | 7/16 - 14 | 52 | M10 | 50 |

| 1 1/2 | 1/2 - 13 | 77 | M12 | 92 |

| 2 | 1/2 - 13 | 77 | M12* | 92 |

| 2 1/2 | 1/2 - 13 | 77 | M12 | 92 |

| 3 | 5/8 - 11 | 155 | M16 | 210 |

| 3 1/2 | 5/8 - 11 | 155 | M16 | 210 |

| 4 | 5/8 - 11 | 155 | M16 | 210 |

| 5 | 5/8 - 11 | 155 | M16 | 210 |

* Does not meet ISO 6162 specifications

| CODE 62 FLANGE RECOMMENDED BOLT TORQUE VALUES | ||||

| Size (in) |

Inch Bolt J518 |

Torque +10% -0 (ft-lb) |

Metric Bolt ISO 6162 (mm) |

Torque +10% -0 N-m |

| 1/2 | 5/16 - 18 | 17 | M8 | 24 |

| 3/4 | 3/8 - 16 | 31 | M10 | 50 |

| 1 | 7/16 - 14 | 52 | M12 | 92 |

| 1 1/4 | 1/2 - 13 | 77 | M14* | 130 |

| 1 1/2 | 5/8 - 11 | 155 | M16 | 210 |

| 2 | 3/4 - 10 | 265 | M20 | 400 |

* Does not meet ISO 6162 specifications

| HYDRAULIC FLANGE RECOMMENDED BOLT TORQUE VALUES | ||

| Socket Screw Bolt Circle (LK) |

Socket Head Cap Screws |

Torque N-m |

| LK35 | M6 | 10 |

| LK40 | M6 | 10 |

| LK55 | M8 | 25 |

Related Information

- How Flange Connections Work

- Hydraulic Flanges and Components - Product Selection

- Free Parker Catalog Download

- Technical Blogs

- More Technical Pages