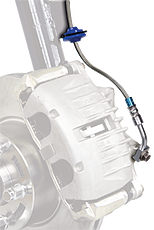

Inspecting brake lines for wear and tear

|

|

The estimated life of a typical 'rubber' brake hose is 6 years, according to BrakeQuip, the manufacturer of aftermarket rubber and high-performance stainless steel braided brake hoses. The actual wear of your brake hoses depends on weather conditions where you drive and store your vehicle, your driving style, etc. Here are some factors influencing the rate of deterioration of your brake hoses:

|

Here is how to check the health of your brake lines:

Check the "feel" of the brake hose assembly

- Brake hose should not be hard and brittle or soft and spongy.

- Brake hose should feel firm but flexible.

Have someone assist you by pumping the brake pedal while you are inspecting the brake hoses. That way, you get to inspect the condition of your brake hoses under pressure. Hose expansion should be barely noticeable under pressure.

HINT: Have the engine running for maximum boost.

Visually check for following brake hose conditions

- Cracks in the outer skin of the brake hose - you may need to bend the hose in order to see this

- Blisters or bubbles in the brake hose - have someone pump the brake pedal so you can see this better

- Chafe marks - from brake hose rubbing against some other component

- Wet stains where brake hose is starting to leak

- Obvious bulging or expansion of the hose

- Loose brake hose mounts

- Twist in the brake line

HINT: All D.O.T. approved brake hoses have two continuous lay-lines (lines of print) on either side of the brake hose, which makes it easy to tell if the hose is twisted.

Other symptoms which may indicate brake hose wear

- Low or spongy brake pedal - may indicate old, soft and weak brake hoses which expand under pressure

- Pulling to one side during braking - may be caused by one of the front brake hoses being blocked or restricted

- Brake drag - may be caused by one or more restricted brake hoses

- Intermitent brake problem - may be caused by a hose with an internal fracture creating a one-way check valve effect

Replacing your worn-out brake hoses

If you detect any of these conditions on any one of your brake lines, you should replace all brake hoses. Hoses deteriorate at the same rate from inside and outside. Since you can only inspect the outside of the brake hose, please fault on the side of safety.

If you need to replace your brake hose, bring your old brake lines to one of our ParkerStores. Usually we can fabricate a new set of brake hoses the same day.

You have two choices when replacing your brake lines

- Rubber brake hoses - Our rubber brake hoses match the original equipment quality and comply with all international standards.

- High-performance stainless steel braided brake lines - Our stainless steel braided brake and clutch lines are D.O.T. approved for use on public roads.

Our BrakeQuip Brake Line Fabrication Systems allow us to make any brake or clutch hose to suit any type of vehicle that operates on brake fluid at a fraction of the dealer's cost. This includes motorcycles, go-karts, medium duty trucks, recreational vehicles and industrial equipment. We pressure test every hose we make to 3000 psi to ensure its safety.